SoftIron Measures Its Carbon Footprint to Make a Point

Since its founding in 2012, London-based software-defined storage provider SoftIron has been making its case for what it calls secure provenance: a term that encompasses the company’s rigorous accounting of the supply chain behind its products, including full control of design and engineering, in-house manufacturing and assembly and authorship of the full software stack. Typically, SoftIron makes this case by invoking the security benefits of secure provenance, but today’s announcement takes a different tack: showcasing the environmental benefits that accompany this direct control by unveiling a carbon footprint of SoftIron storage solutions.

The footprint

The carbon footprint was conducted by Earth Capital, a sustainability-oriented investment firm and one of SoftIron’s earliest investors. The footprint first evaluates the end-to-end emissions of a SoftIron HyperDrive HD11120 node, placing them around 2,898kg (±290kg) of CO2 equivalent (CO2e)—equivalent to burning about 300 to 350 gallons of gasoline.

The vast bulk of this (around 2,227kg CO2e, nearly 77 percent of the total footprint) stems from electricity use across five years of operating the node, while most of the remainder (483kg CO2e, or ~17 percent) stems from production of the PCB itself. (It’s worth noting that Earth Capital assigns zero emissions to end-of-life for the node “as no sold/installed product has reached end-of-life.”)

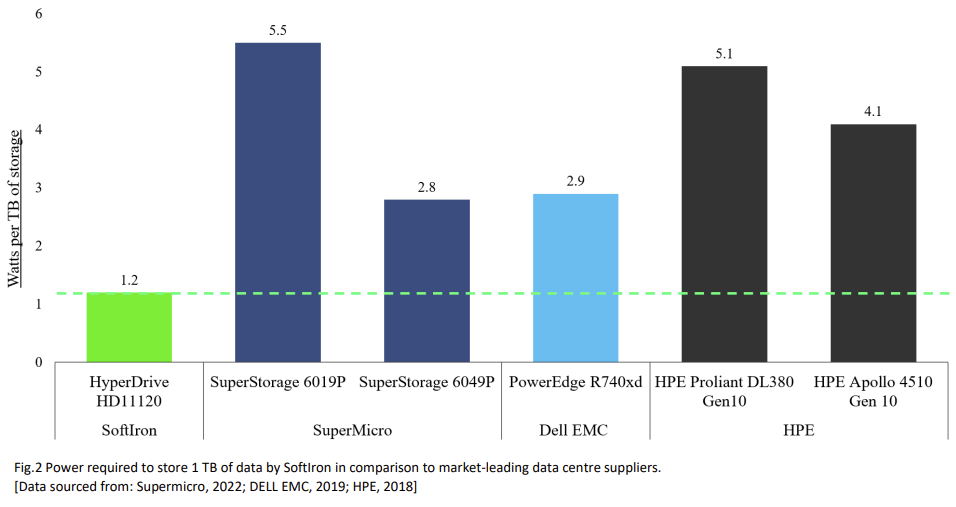

The footprint then hones in on those emissions from electricity use during operation, comparing SoftIron’s solution to similar solutions from Dell EMC (PowerEdge R740xd), HPE (Proliant DL380 Gen10, Apollo 4510 Gen10) and SuperMicro (SuperStorage 6019P, SuperStorage 6049P). The report finds that compared to the energy use of the HyperDrive HD11120 (1.2 gigawatt-hours per petabyte), the competitors required ~2.3× the energy (SuperMicro’s SuperStorage 6049P, 2.8GWh/PB) to ~4.6× the energy (SuperMicro’s SuperStorage 6019P, 5.5 GWh/PB).

Average the energy needs of those competing products, extrapolate the energy difference between SoftIron’s product and that averaged value over a five-year lifetime and multiply by standard emission factors, and you get SoftIron’s headline claim: that, via energy savings alone, around 292 tons of CO2e are saved for each 10PB of SoftIron storage that’s shipped instead of storage from its competitors. To get a sense of scale, that’s around the annual emissions from 57 average homes.

Why the difference?

SoftIron attributes this differential to its specialized products’ much smaller footprints and lack of “fat” compared to general-purpose solutions. “Everyone’s focused on ‘you take a generic piece of hardware and then you just pile the software on top to make the differentiation,’” said Phil Straw, co-founder and CEO of SoftIron, in an interview with HPCwire. “I believe the industry’s ready for a reciprocal story, which is: if you care about sustainability, the hardware really matters.”

Straw said that the sustainability advantage of SoftIron likely extends well beyond energy use, citing the company’s more local, centralized “edge manufacturing” (which requires less shipping of components and products) and lower operating temperatures (which would likely indicate longer product lifetimes).

But Straw says that this sustainability advantage is just the result of common sense. “We’re not on some kind of green cause, necessarily—I mean, it’s just stupid to mess up the planet,” he said. But beyond that, he argued, “the way that things are built and manufactured and distributed is also 20 years old,” and the opportunities that led to SoftIron’s comparative sustainability are “a result of a stale industry that is ripe for disruption.”

Business implications

Craig Chadwell, VP of product for SoftIron, told HPCwire that clients are taking notice—and not just out of the goodness of their hearts. “There’s the sustainability angle to this conversation, but there’s also the fact that more and more data is moving outside of the traditional datacenter into these edge locations,” he said. “And the reality is that these edge locations just don’t have the same kind of power budget or environmental budget that facilities that were designed and built to operate datacenter infrastructure have.”

“We’ve got a client in the UK who is avoiding having to buy additional racks,” he continued, “just based on the fact that they are flipping out their old Isilon equipment for similar, but newer and better-performing … technologies from SoftIron that’re basically going to give them double the density in one-third the rack space and also cut their power budget.”

With those advantages in mind, SoftIron is working hard on expanding. The company last raised $34M in Series B funding—bringing it to some $50M—and is now raising money for a Series C, Straw said. At least three nation-states, he said, are also paying SoftIron to build factories, and new “megafactories” are planned for the U.S. “We also have contracts with government agencies that focus on ecologically sustainable computing,” Chadwell said, noting that testing is ongoing and results should be available soon.