‘AI Camera’ Combines Machine Vision, Deep Learning

Is it any wonder there are cameras everywhere imaging nearly everything? One reason is chip scaling, with key components from semiconductor makers allowing equipment manufacturers to fabricate quarter-size cameras that are becoming ubiquitous in agricultural, automotive and industrial markets.

Now, inspection camera manufacturers are adding smarts in the form of image processing that according to one vendor brings “AI to the edge” in the form of a machine vision camera with deep learning inference capabilities.

The marketing pitch for this approach centers on the proposition that placing deep neural network acceleration directly on a camera allows inference to be performed at the network edge, eliminating the need to transmit a raw video stream elsewhere for processing.

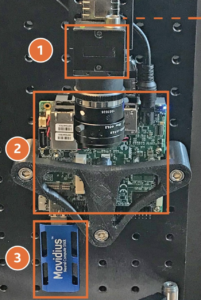

An “AI camera” unveiled this week by thermal imaging specialist FLIR Systems Inc. (NASDAQ: FLIR) is based on Intel Corp.’s (NASDAQ: INTC) Movidius Neural Compute Stick that is built around its Myriad 2 vision processing unit. The camera maker said this week it used the USB-based Movidius AI acceleratorto prototype its AI camera dubbed “Firefly.”

FLIR Systems, Wilsonville, Oregon, said the combination of the Movidius stick and the accompanying software development kit enabled it to accelerate prototyping. The Movidius VPU includes onboard image signal processing along with a CPU. FLIR Systems used onboard imaging along with a convolutional neural network and programmable compute capabilities to significantly reduce camera size, weight and power consumption, the partners said.

Once the prototype camera was ready for commercial production, it was ported to the Movidius Myriad 2 VPU. The production version uses the VPU for image signal processing and “open platform” inference, the company said Thursday (Oct. 18).

The resulting 27-by-27-millimeter camera, roughly an inch square, is about the size of a U.S. 25-cent coin.

The tiny camera with deep learning inference capabilities is being aimed at a range of “precision” agricultural, industrial, security and even medical imaging applications. The combination of machine vision and deep learning is being promoted as a possible tool for “complex and subjective” problems such as product inspection or determining whether crops are ready for harvest and whether harvested fruits are “export quality,” as in no bruises.

For manufacturing, the camera maker pitches the AI camera as a way of inspecting wares and classifying product quality as items come off the assembly line. For example, the camera would use pass/fail inferences while inspecting the quality of manufactured components.

Along with biometric and other security applications, the partners said the inspection camera could be used for medical imaging applications such as “first-pass screening” of biopsies or as a way of identifying false negatives.

The goal “is to subjectively analyze visual information,” said Mike Fussell, FLIR Systems’ product marketing manager. For instance, the camera could be used to inspect a manufactured part and “identify defects that no one has ever seen before or even anticipated seeing. The result will be automation of visual tasks that previously could only be handled by humans,” Fussell added.

The initial production version of the camera uses a 1.6-megapixel CMOS image processor from Sony Corp. (NYSE: SNE) on the front end and the Movidius Myriad 2 VPU for deep neural network inference.

Related

George Leopold has written about science and technology for more than 30 years, focusing on electronics and aerospace technology. He previously served as executive editor of Electronic Engineering Times. Leopold is the author of "Calculated Risk: The Supersonic Life and Times of Gus Grissom" (Purdue University Press, 2016).