Energy Project Leverages AI for 3D Manufacturing

A federal energy research initiative is gaining momentum with the release of a contract award aimed at using supercomputing to harness 3D printing technology that would boost the performance of power generators.

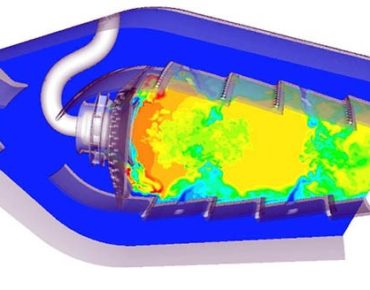

Partners GE Research, PARC, the Xerox research arm, and Oak Ridge National Laboratory will investigate methods for reducing design timelines for printed components used in power systems ranging from wind to gas turbines. Under a $1.3 million contract awarded by the Advanced Research Projects Agency-Energy, (ARPA-E), the partners will use the national lab’s Summit supercomputer to develop machine learning frameworks.

The goal is to halve design timelines for 3D-manufactured components for turbomachinery applications by leveraging AI models to complete millions of design iterations. The partners will seek to reduce 3D components design times to as little as one year.

The HPC-driven research is part of an ARPA-E initiative called DIFFERENTIATE, mercifully short for Design Intelligence Fostering Formidable Energy Reduction (and) Enabling Novel Totally Impactful Advanced Technology Enhancements. The energy ML effort targets math optimization problems common to energy and other system design processes.

The newest effort takes that approach a step further by leveraging emerging 3D printing technology to hasten the design and deployment of new turbo-machinery components.

Read the full story here at sister web site HPCwire.

Related

George Leopold has written about science and technology for more than 30 years, focusing on electronics and aerospace technology. He previously served as executive editor of Electronic Engineering Times. Leopold is the author of "Calculated Risk: The Supersonic Life and Times of Gus Grissom" (Purdue University Press, 2016).