3D Printing Meets Augmented Reality

3D printing is already labeled as a “cutting edge” or “next-gen” technology by many, but when you throw augmented reality into the equation, it is easy to feel like we're living in a Star Trek-style holodeck.

3D printing is known for creating entire objects out of metal or plastic, right out of thin air. Meanwhile, augmented reality systems can create analogous virtual objects out of thin air as well, so long as it does so in a virtual space. While it might not seem like these two technologies have a lot in common, their creators saw a natural joining point.

3D printing is known for creating entire objects out of metal or plastic, right out of thin air. Meanwhile, augmented reality systems can create analogous virtual objects out of thin air as well, so long as it does so in a virtual space. While it might not seem like these two technologies have a lot in common, their creators saw a natural joining point.

Sander Veenhof and Joris van Tubergen, of the Netherlands, joined their skills in media art and design to make this technological merger a reality.

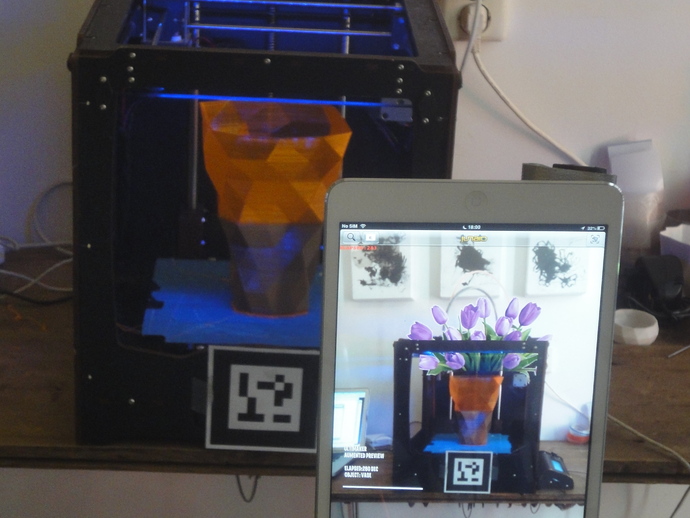

The concept, called the “UltimARker” allows owners of Ultimaker 3D printers to get a real–time preview of their 3D projects. The UltimARker not only shows what the designs will eventually look like but also displays information such as how long it will take to complete the project.

“UltimARker” is a play on the open-source 3D printer known as “Ultimaker.” Presented at Brooklyn's Botacon in 2010, the Ultimaker 3D printer prototype not only printed on a larger scale but it also printed faster than its competitor, MakerBot.

The company boasts about its printing speeds and in a blog post stated that the Ultimaker “reached printing speeds of 350mm/s during travel and 300m/s during extrusion.” Even MakerBot cofounder, Bre Pettis, was quoted saying, “They can move their machine around at a pretty amazing speed. There are some things they did that are pretty clever.”

Ultimaker uses ABS or PLA plastic to print, although they recommend using PLA because it’s faster and more stable. When compared to the MakerBot printers it weighs in at a little over a third of its competitor's weight and swaps out a moving build platform for a moving print head.

With the Ultimaker becoming a popular desktop 3D-printing option for additive manufacturing hobbyists, Veenhof and Tubergen hope their technology will only expand from here. Already on UltimARker's Thingiverse page, the team has asked that someone in the open source community will take their technology one step closer by merging it with Google's new augmented reality eyewear, “Glass.”

Full story at VentureBeat