HPC Helps Put Mercury Marine in Front of its Competitors

There are five major manufacturers of outboard motors in the world today, and only one of them is headquartered in the U.S.

There are five major manufacturers of outboard motors in the world today, and only one of them is headquartered in the U.S.

Mercury Marine of Fond du Lac, Wisc., is not only holding its own, but is doing quite well against competitors Yamaha, Suzuki, Honda, and Evinrude. Among Mercury’s offerings are outboard engines ranging from 2.5 hp to 350 hp, powerful sterndrive engines rated at 135 hp to 1250 hp, as well as a variety of integrated electronics, parts and accessories.

The company got its start in 1939 as the Kiekhaefer Corp. (later Kiekhaefer Marine). In 1961, it was acquired by Brunswick Corporation, known for its bowling, boating, billiards, and fitness products. When founder Carl Keikhaefer resigned from the company in 1969, it was renamed Mercury Marine.

Fast-forward 50 years. We are now in an era of globalization and fierce competition. To effectively contend with its four overseas challengers, 72-year-old Mercury is embracing the latest in 21st century digital manufacturing techniques.

Last December, at an HPC 360 conference sponsored by R Systems, Arden Anderson, an engineer with Mercury’s product development and engineering organization, described how the company is using high-performance computing (HPC) to design what Mercury claims is “the most comprehensive product offering in recreational marine.”

Anderson recently brought us up to date on his organization’s HPC activities and plans for the future.

Mercury Marine first dipped its toe into the HPC waters in 2004, beginning with UNIX-based workstations and progressing over the next several years to a loose cluster of 12 Linux-based workstations. These systems allowed Mercury Marine to enhance its capabilities in finite element analysis (FEA) and computational fluid dynamics (CFD) .

In 2009 the group made a major upgrade, switching from a “carpet cluster” of Linux workstations to a four-node (32 core) computing cluster running Microsoft Windows HPC Server 2008. A year later the group added 48 cores to the existing server for a total of 80 cores to further boost its FEA/CFD capabilities.

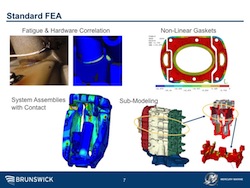

FEA – used for simulating stresses on structures such as engine components, bolted assemblies, and brackets – accounts for about 70 percent of the system compute time.

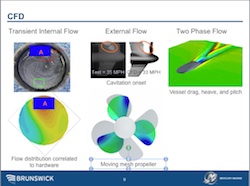

CFD – used for simulating fluid dynamics such as transient internal flows, external flows and cavitation around the propeller, and vessel drag, heave and pitch – accounts for the other 30 percent.

“The evolution of our HPC system over the past five years has lead to greater throughput and increased capabilities,” says Anderson. “Our latest HPC server has delivered improvements in run times as high as 8x at a very affordable price. Smaller jobs are executing five times faster. Not only are the newer computers faster in terms of CPU speeds, they are also more powerful due to increased RAM and a greater ability to handle parallelization. This means we can tackle larger jobs and meet the demands of a very fast-paced product development cycle.”

Anderson notes that a faster and more powerful system also means that the engineers can include more detail in the simulations. In fact, including more detail actually makes the work go more quickly. He explains, “For example, de-featuring something like a hole or fillet to accommodate a less powerful HPC system takes analyst pre-processing time and reduces the accuracy and realism of the simulation. This is also true for many kinds of modeling abstractions, such as bolted joints (full contact vs. a ‘glued interface’) or converting a solid geometry to shell elements. The bottom line is that abstractions take engineering time and reduce realism; more powerful computers allow analysts to make fewer abstractions.”

Auto-meshing also saves pre-processing time. As fewer abstractions have to be employed, the automatic part of auto-meshing becomes even more effective, requiring less analyst time for setup, guidance and other forms of interaction.

The Windows HPC Server 2008 Job Scheduler allows the team to efficiently manage computing resources throughout the cluster. About 10 analysts share this resource. Anderson says the job scheduler is very easy to use. “It requires little or no training, is easy to setup, makes no changes to our regular workflow, and maximizes the utilization of the compute cycles on the cluster.”

The benefits of the more powerful HPC system allow Mercury Marine engineers to do extensive virtual testing before conducting physical tests. For example, using the FEA capabilities provided by their software of choice – the SIMULIA Abaqus FEA product suite – Anderson’s team conducts extensive crashworthiness tests.

“Since deploying the HPC systems, a virtual crash test runs in a matter of days instead of weeks,” he says. “And the virtual tests also provide more insight into the system’s behavior during these split-second impact events, whereas this level of detail is difficult to record and study from a physical crash test. Overall, the capabilities of our current HPC system allow us to increase the durability, reliability and weight optimization of our products. And this makes us more competitive.”

As for the future, Anderson says Mercury Marine is considering using cloud services from a company like R Systems. “I can see us cloudbursting if we are doing some very intense computing, such as stochastic modeling or Monte Carlo simulations. Another scenario is to deal with overflow when there are more projects in-house than we can handle on our internal HPC cluster.

“But whether the modeling and simulation is in-house or run in the cloud, there is no question that HPC allows us to excel in a very tough marketplace,” Anderson concludes.