How To Make a Safer, More Comfortable Firefighter’s Mask

What's your head shape? Are you oval like an egg, round like a pumpkin, or maybe more like a turnip?

Your cranial configuration literally becomes a burning issue if you happen to be a firefighter. In addition to gloves, helmets, jacket and boots, one of a firefighters most essential pieces of equipment is the respirator mask.

Problem is that until recently, these masks have been designed to a "one size fits all" specification. Trouble is, they don't. Silicon rubber only stretches so far and what may work for a turnip head won't protect someone with a noggin that more closely resembles a shoebox.

Problem is that until recently, these masks have been designed to a "one size fits all" specification. Trouble is, they don't. Silicon rubber only stretches so far and what may work for a turnip head won't protect someone with a noggin that more closely resembles a shoebox.

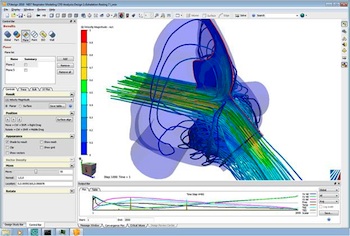

This is why the National Institute of Science and Technology (NIST) enlisted Predictive Engineering to investigate reconfiguring the masks to minimize air leakage and the threat of contamination. Predictive, in turn, fired up their FEA and Autodesk Simulation CFD software to explore the complex interactions inside various mask configurations.

Luke Mihelcic, product marketing manger for the Autodesk Simulation Division, points out that physical testing was ruled out because of the difficulty of measuring or seeing what is happening inside the mask when it is being worn.

Luke Mihelcic, product marketing manger for the Autodesk Simulation Division, points out that physical testing was ruled out because of the difficulty of measuring or seeing what is happening inside the mask when it is being worn.

"What CFD simulation allows Predictive to do is measure the inside of the simulated mask to determine air flow, pressure drops, recirculation, stagnant zones — you name it," he says. "You can slide and dice the model or simulation any way you want."

The project has uncovered some interesting anomalies. For example, past simulations modeled the texture of the face as if it were semi-elastic rubber. From its FEA analysis, Predictive found that this lead to false readings; it is far more accurate to model the face as if it is a bag containing viscous fluid that can be deformed in many subtle ways when the mask is pressing up against simulated flesh.

The Autodesk CFD design environment allowed Predictive engineers to view the results of multiple simulations on a single screen. Mihelcic explains that traditional environments only display one simulation a time — now the researcher can compare qualitative and quantitative results from say, six screens at once.

The Autodesk CFD design environment allowed Predictive engineers to view the results of multiple simulations on a single screen. Mihelcic explains that traditional environments only display one simulation a time — now the researcher can compare qualitative and quantitative results from say, six screens at once.

George Laird, the CEO/owner of Predictive Engineering, also comments in this video on the ease of use of the CFD software. For example, the expected three week turnaround for the project took only a few days because of the robustness and ease of use of the Autodesk product.

The bottom line, says Mihelcic, is that the CFD simulation revealed that satisfactory results could be obtained with some minor tweaks. However, he cautions, "When dealing with fluids and thermal simulation, minor changes can have a pretty drastic impact on the way the fluids move or the thermal profile behaves inside the simulation."

For example, a sharp edge in a design can cause recirculation issues, pressure drops and stagnation. But as soon as the edge is smoothed and the fluid can flow unimpeded, these issues are resolved.

Says Mihelcic, "In our world, small tweaks are a big thing."