Case Study: AAI Corporation Builds Competitiveness with HPC and the ‘Black Art’ of Computational Fluid Dynamics

A few years ago, AAI Corporation hired Dr. Michael Guterres to lead its Aircraft Engineering Department. The company knew it had to elevate its design capabilities to be more competitive in the unmanned aerial vehicle (UAV) marketplace. However, it had no specific plan to improve its computational abilities. Guterres recognized the need for expanded computational fluid dynamics (CFD) capabilities that could only run on a powerful high performance computing (HPC) cluster.

"When I came on board, there was not much interest in CFD — it was perceived as something we really didn't need," Guterres recalls. "So, based on my previous experience, which gave my ideas credibility, I demonstrated the benefits of CFD to management. AAI's management was very receptive."

"When I came on board, there was not much interest in CFD — it was perceived as something we really didn't need," Guterres recalls. "So, based on my previous experience, which gave my ideas credibility, I demonstrated the benefits of CFD to management. AAI's management was very receptive."

His business case to management for the new hardware and software included the substantial return on investment (ROI) that could be realized by compressing the design cycle and creating virtual wind tunnel environments to reduce physical prototype testing and exploratory flight testing. The investment, he said, would also result in a substantial ramp up in the company's competitive position. Guterres' proposal was accepted, and AAI moved rapidly into a new era of advanced UAV design. Since 2006, AAI has used CFD and HPC on 48 internally and externally funded product development and R&D projects.

Headquartered in Hunt Valley, Md., AAI provides its customers with innovative aerospace and defense technologies. The company, an operating unit of Textron Systems Corporation, has 2,600 employees and posted annual sales of $663 million in 2007.

A typical example of the UAVs Guterres and his colleagues work on is AAI's highly-regarded Shadow 200 (see Figure 1), part of the Shadow family of tactical unmanned aircraft systems in service to both the U.S. Army and U.S. Marine Corps. Unmanned aircraft are extremely popular platforms that incorporate sophisticated, intelligence-gathering payloads to collect battlefield and situational awareness information, and then relay this information to operators on the ground. This gives the warfighters carrying out missions crucial data they need to act decisively.

To design these small but complex aircraft, CFD is one of the key tools Guterres and his group rely on — a branch of fluid mechanics that uses numerical methods and algorithms to tackle problems associated with fluid flows. To the uninitiated, using CFD to help design a UAV wing, landing gear or fuselage would seem to be a fairly straightforward proposition. But it is not.

"CFD is a bit of a black art," Guterres says. The use of CFD tools requires a lot of expert knowledge in the initial modeling of the problem and evaluation and verification of the results. Despite its development over decades and the awesome computational capabilities of today's high-performance computers, in many cases CFD still only provides approximate solutions. To fill in the gaps, Guterres relies on comparisons with flight data and wind tunnel data as well as experience and intuition based on a long familiarity with this esoteric branch of fluid mechanics — his own version of applied sorcery.

CFD has, in fact, come a long way from its beginnings in the 1960s. Advances in computing — in particular HPC clusters and powerful modeling and simulation software — have provided the horsepower necessary to get more accurate results from CFD. Powerful computers have been indispensable in solving what have been called a "truly hairy" set of non-linear differential equations. These Navier-Stokes equations are used to solve laminar and turbulent fluid flows and are fundamental to CFD. In AAI's UAV work, the sheer amount of information needed to simulate the interaction of the flow of air over the aircraft's various surfaces can tax the capabilities of even the most robust HPC system.

Figure 1. Shadow 200 RQ-7B in operation

Meeting the Challenges

The very nature of the aircraft Guterres and his colleagues at AAI design brings with it a set of challenges that can best be addressed by the group's HPC and CFD capabilities.

"Manned aircraft companies need several years to design, build and test aircraft," he says. "But our business is different — we are a military intelligence asset, our aircraft weigh less than a thousand pounds, and we don't have man onboard. One of the main appeals of small UAVs to our customers is that they can perform very useful intelligence missions at a cost per flight hour that is a significantly lower than a manned platform and with a much smaller infrastructure footprint. In addition, our development cycle is very compressed. We move from a set of requirements to a concept, through preliminary design and a prototype, and then to a final product that is operationally ready in less than half the time needed for a manned platform."

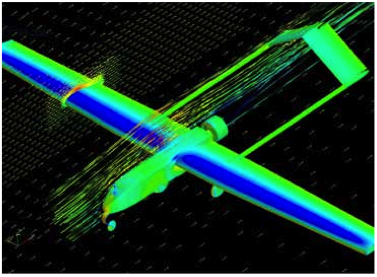

Figure 2. Shadow RQ-7B IE RANS CFD solution

The need to move rapidly through the development lifecycle has led AAI aeronautical engineers to depart from the classical airplane design approach when it comes to wind tunnel testing and scale model flight testing. These two approaches are very valuable in aircraft design, but are time consuming and costly. A physical model has to be constructed, and major iterations on the design require a new model and a new test schedule.

Through the use of a powerful HPC cluster, advanced software and highly-skilled engineers, the UAV designers have taken their CFD capability to a new level (see Figure 2). As a result, they are able to simulate a virtual wind tunnel environment and gather accurate data. "Being able to simulate the aerodynamic environment allows us to accelerate the development cycle, save a significant amount of money and reduce risk in the program," Guterres notes.

Having said that, he also points out that CFD is not a replacement for wind tunnel tests or a thorough aerodynamic evaluation in a controlled environment. Rather, it is a valuable tool that places the designer close to the final solution with reduced risk. The computer-based simulation allows the engineers to quickly evaluate different configurations, modifications and payloads at an early design stage. Wind tunnel testing is then used for evaluation of critical data that CFD cannot provide accurately. Not only is there a cost savings, but the use of HPC also generates significant ROI for research and development efforts.

Guterres says: "Bottom line — we hit the target requirements, get the job done faster, and deliver the finished product to the customer in a much shorter time frame compared to the days when we did not have the ability to model complex aerodynamics reliably."

Advanced Hardware and Software, and More

The Aircraft Design and Engineering group relies on a five-node HPC cluster, each powered by 4 Intel Xeon multicore processors with 88GB of RAM and an auxiliary 9.3 terabyte storage device dedicated to the CFD simulation data. They also use commercial software (STAR-CCM+) from CD-adapco, a New York and London based software company. The software supports the entire process, from CAD preparation to creating the necessary mesh (or "grids") to model set-up and iterative design studies. STAR-CCM+ includes features such as built-in surface wrapping, advanced automated meshing, and the ability to copy and paste components between models. "These commercial codes are really very powerful and useful," Guterres says.

In addition, Guterres points to another invaluable resource — bringing on board highly motivated engineers who are interested in analysis and want to learn more about the use of HPC to solve CFD and other aerodynamic problems. "These are very smart, motivated folks who have been making great strides in our field due to a combination of in-house and on-the-job training, self-learning driven by their own curiosity and formal teaching in the form of seminars, workshops and conferences. Also, they have had a lot of interaction with the people at CD-adapco who actually developed the CFD code. This has morphed into a two-way relationship — our engineers have not only gotten great guidance from CD-adapco, but as their expertise has grown, they have helped the STAR-CCM+ developers evolve their software."

CFD at Work — Landing Gear, Propellers and Fuselages

Typically, in the preliminary design stages, the engineers use lower-level aerodynamic codes to perform initial sizing of the wings and tail and design components like airfoils and some of the aerodynamic control surfaces.

Once they have the preliminary design roughed in, it is time to turn to CFD for a more refined optimization of the vehicle. For example, this will include a close look at the various concepts being considered for the UAV's landing gear. Because landing gear for this type of aircraft can account for up to 25 percent of the airplane's drag, its design has a major impact on performance and endurance — i.e., how fast can the aircraft go, how high it can fly and how much fuel it needs to perform its mission.

These are tactical vehicles being used by soldiers often in rough environments. A fixed, simple landing gear works best for a ruggedly designed UAV — the fewer moving parts the better. But, Guterres points out, the exposed landing gear also has a big impact on how long it can fly during a surveillance mission, the UAV's primary job. "If I can get the airplane to fly six hours instead of five and a half through designs optimized by using HPC, that's a big improvement for our customers," he says.

At this point in the development cycle, the engineers may be considering three or four different landing gear designs. They now model the various landing gear shapes in CFD using the HPC cluster. This approach allows them to solve the flow field around the entire airplane and evaluate which one of the landing gear designs is the most beneficial from an aerodynamic standpoint — which produces the least drag.

"By using HPC, we can evaluate four landing gear designs in a period of two weeks," Guterres says. "In many programs, we could not motivate the cost of a physical test for a subcomponent such as a landing gear. Therefore we would simply not have the data and would be sub-optimizing the design. Using HPC gives us insights we would not have otherwise, because once the infrastructure and the talent are in place, we can tap into it easily."

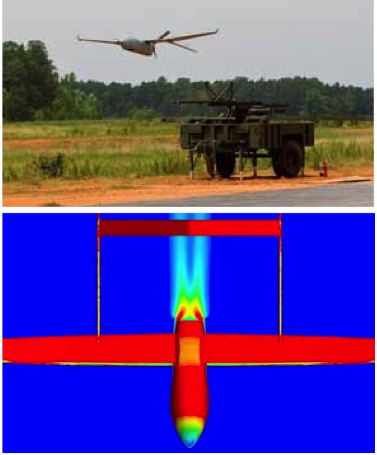

Figure 3. Top: AAI's Aerosonde MK4.7 in flight; bottom: MK4.7 in CFD

Another example of CFD and HPC in action is fuselage design. For example, the engineers have to determine how to optimize payload volume and how the fuselage mates up with the engine. In most UAV designs, the engine is in the back, and access to cooling air is a major issue. Often the aft section of the fuselage just in front of the engine has to be modified for improved performance. CFD allows the engineers to quickly evaluate three or four different designs and select the one that provides the best airflow for cooling the engine. Such an example is the design of the Aerosonde MK4.7 fuselage (see Figure 3 above) where CFD and HPC were heavily used to optimize available payload volume without compromising the aircraft's flight performance or the engine cooling conditions.

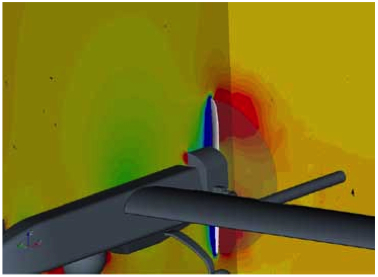

The fluid dynamics associated with propellers also present highly complex problems that the engineers would be hard-pressed to solve without the help of HPC (see Figure 4).

A propeller rotating at 5,000 rpm produces extraordinarily complex air flows. The propeller blade is essentially a high aspect ratio wing whose thickness and shape changes at every section of the blade. Now imagine the aerodynamic ruckus created when three or four of these rapidly spinning propellers are flying through the turbulence generated by their neighbors' aerodynamic wakes. But creating a CAD model that can be simulated using HPC has allowed AAI aeronautical engineers to solve the axisymmetric rotating flow

of air generated when the blades are interacting with each other.

Guterres says: "We got to a point where we actually generated installed pusher propeller CFD simulations that matched flight data dead on. That was a great moment. Now we can modify the shape of the blade parametrically and find an optimum design. Not a lot of people have done this with full 3D RANS CFD in the wake of a pusher aircraft — we're really breaking new ground here."

Another typical scenario occurs when a customer decides to change the payload on an existing aircraft, which triggers a fuselage evaluation to accommodate the new equipment. Considerations include the impact on the weight of the airplane, its drag and the amount of airflow over the rear-mounted propeller, which dictates the thrust it can generate and engine cooling.

Figure 4. AAI's Installed Propeller Flow Modeling with CFD and HPC — Pressure Plot

Without HPC, AAI engineers would use their best engineering judgment and available CAD workstations to re-design the aircraft to meet the new specifications. This is risky.

"Without HPC, I may not be able to design an optimum fuselage — one that allows the UAV to carry a bigger payload, but still retains its ability to fly fast, high and far," Guterres says. "If I'm just sketching out the design without doing the kind of rigorous analysis HPC makes possible, I may not meet the customer's requirements or do so at a non optimum point, reducing our competitiveness."

"So," he concludes, "the use of high performance computing and advanced CFD software allows us to keep our customers happy, be more competitive and maintain our position as a premier supplier of tactical unmanned aircraft systems. It is important to note however that this is not black box engineering. The engineering team needs to know how to use the CFD tools and when to use them. The experience and knowledge of the design team is of critical importance in the effective use of CFD and HPC as applied to aircraft design."

About the Project

This case study was produced as part of a project that was created to demonstrate the business and competitive value of modeling, simulation and analysis with HPC in the U.S. private sector, motivate usage of this innovation-accelerating technology throughout the DoD's supply chain, and identify technologies and partners that can help support an HPC infrastructure for the DoD supply chain base. It was led by the University of Southern California's Information Sciences Institute (ISI) and supported by funding from the Defense Advanced Research Projects Agency (DARPA) under contract number FA8750-08-C-0184. DARPA is the central research and development office for the U.S. Department of Defense. DARPA's mission is to maintain the technological superiority of the U.S. military and prevent technological surprise from harming our national security. For more information, see http://www.darpa.mil.

Complete information about the other case studies and pilot programs associated with this project is available at http://www.compete.org/hpc/darpapilots/.

Reprinted with permission of the Council on Competitiveness