Additive Manufacturing Shakes Up Industry

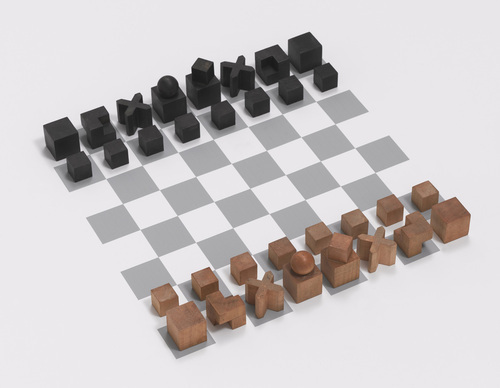

Additive-manufacturing processes like 3D printing are paving the way for new business models and new ways of thinking about the design process. In 3D printing, a material, usually plastic, is deposited in layers until the desired object is achieved, allowing enthusiasts to create everything from missing chess pieces to designer lamps. Another additive-manufacturing technique, stereolithography, while generally more expensive than 3D printing, can be used to create very refined surfaces. In this approach, a laser beam is applied to a light-sensitive liquid resin polymer, hardening it into thin slices that adhere to the layer below.

MIT's Technology Review has reported on some of the benefits and drawbacks of this ascending technology. On the plus side, 3D printing can generate the sort of unique or intricate geometric shapes that would not be feasible using traditional methods, especially where mass production is a goal. The fact that this is a digital technology means that it can be reproduced anywhere as often as necessary. Once the design is saved on a 3D CAD file, the product can be manufactured (printed) as many times as is desired. Minimum and maximum order constraints are virtually eliminated as are some the headaches associated with having to "guestimate" product demand.

MIT's Technology Review has reported on some of the benefits and drawbacks of this ascending technology. On the plus side, 3D printing can generate the sort of unique or intricate geometric shapes that would not be feasible using traditional methods, especially where mass production is a goal. The fact that this is a digital technology means that it can be reproduced anywhere as often as necessary. Once the design is saved on a 3D CAD file, the product can be manufactured (printed) as many times as is desired. Minimum and maximum order constraints are virtually eliminated as are some the headaches associated with having to "guestimate" product demand.

According to analyst data cited in the article, globally more than 100 companies employ some type of 3D additive manufacturing process. Although still used largely for prototyping, actual product manufacturing is increasing, and industrial scanners, furniture, and medical equipment are among the many items being produced with the technology. In May, stalwart General Electric revealed it was increasing its reliance on additive manufacturing techniques to create components for things like aircraft engines and ultrasound machines.

Of course there are tradeoffs to be made with any technology. With additive manufacturing, printer size dictates the dimensions of the end product. Additionally, the process only works with certain materials and does not easily support the use of more than one material.